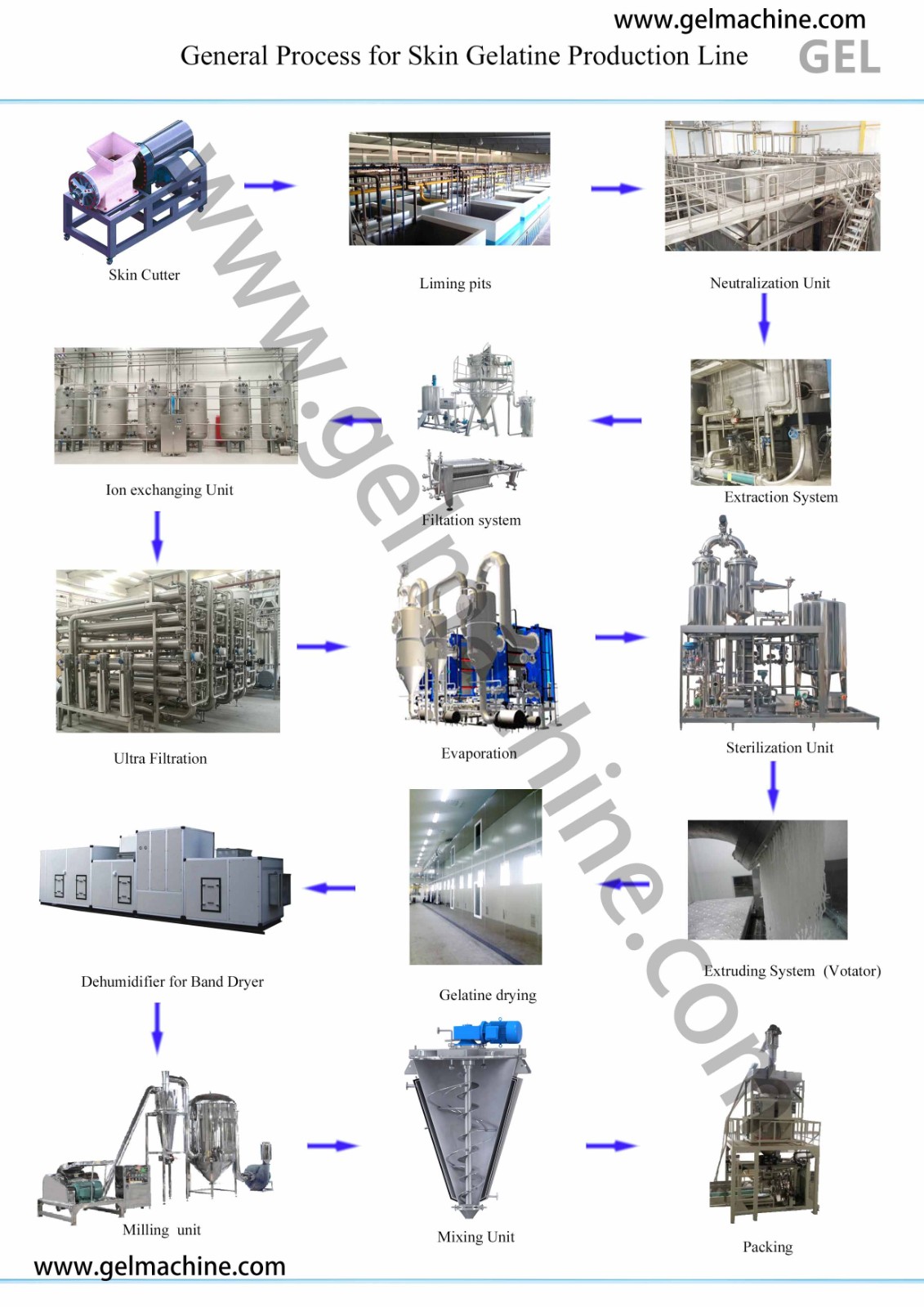

Skin Gelatine Production Line

Gelatine is made of native collagenous raw materials which are derived from the connective tissues from animals, such as bones, skin and fish scale. For skin raw material, the most widely used raw materials are pig skin and hide split. The skin gelatine manufacturing process makes the collagen soluble in hot water. The incoming raw material is first washed with water and pretreated with acid or alkali. The pretreatment may be a short time soaked in a dilute acid solution or a prolonged soak in a saturated lime solution. Gelatine derived from acid-cured tissue is known as Type A Gelatine. Gelatin derived from alkali-cured tissue is known as Type B Gelatine.

After pretreatment from chemicals, the skin or hide split is once more washed with water and the PH value will be adjusted to a desired value, we call this process"washing and neutralization"

The washed and neutralized gelatine raw material is then extracted with either a continuous process or with a series of applications of warm water at progressively higher temperature. Each successive extraction yields gelatine of lower gel strength and viscosity.

The following gelatine production steps are filtration, ion exchanging, evaporation, sterilization, extruding, drying, milling, mixing and packing. Please see the following skin/hide split gelatiane process flow chart: