The purified, high-concentrated gelatine solution is sterilized at temperature of up to 140℃ in a high-temperature sterilizer, solidified in special coolers, and finally pressed through perforated plates. The noodle-shaped gel thus produced is dried on horizontal belt dryer with purified, dehumidified clean air. The dried gelatine is broken at the output of the dryer, coarsely ground and temporarily stored in batches.

During the drying process, the highly concentrated solution gels and is extruded in the form of “noodles” that are fed onto the conveyor belt of a dryer. Then the residual water is gently removed using filtered, dehumidified and microbiologically clean air.

Because of its low melting point, gelatine cannot be dried using direct warm air, thus, initially, the relative humidity of the drying air is 10-15%. The temperature of the air is initially about 30℃, and this is gradually increased according to the degree of the dryness of the gelatine, in this way, the ability of the air to absorb water increase. By the end of the process, the air at about 60℃, has a high humidity. The gelatine leaves on the drier in the form of a woven carpet of noodles with a water content of about 10%.

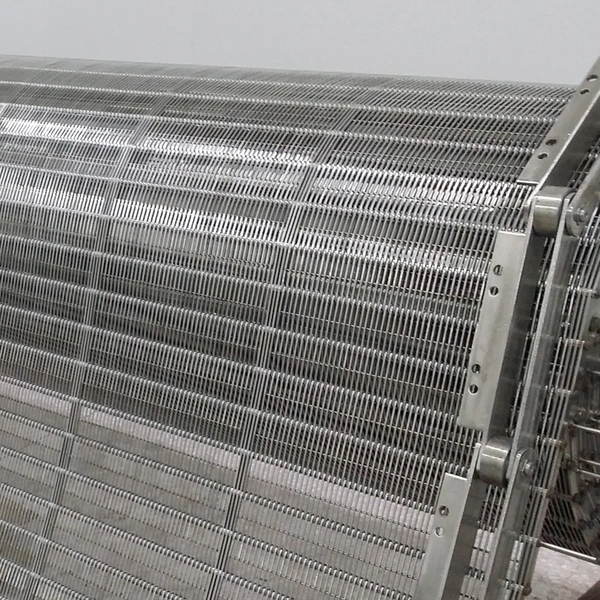

The effect of the dry air on the surface of the noodle is to form a dry skin sufficient to prevent the sol-gel change of state from being reversed when the air temperature is progressively increased to maintain the hygroscopic differential between the drying gelatine and the drying media. From the dividing conveyor the gelatine is transported on to a stainless steel main belt, which runs through the gelatine-drying tunnel.

Alternately, the dry air from the dehumidifier is passed in cross-flow through the layers of the gelatine. The gelatine-drying tunnel is divided into zones, each maintaining a different temperature.

In the first zone the supply air temperature, which comes direct from dehumdifier, is approx. 40°C and in the last zone the air is heated until 60°C.

The front part of the band dryer can be furnished with a hygienic e.g. cooling zone. The back part of the band dryer can be furnished with an after cooling zone. All parts are made of stainless steel and odour- and/or tasteless rubber.

The frame is made of galvanized profiles and the side panels are constructed of aluminium-clad plywood or stainless steel with adequate inspection doors.